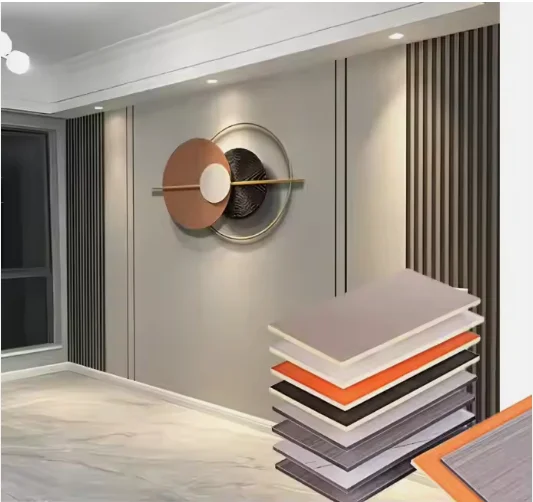

PVC foam board is waterproof, flame retardant, acid and alkali resistant, water-proof, lightweight,heat-insulating,sound-insulating and shock-absorbing. The surface of crust foam board is very smooth, with high hardness and is not easy to be scratched. This foam board is often used to make cabinets, furniture, advertising board.

[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

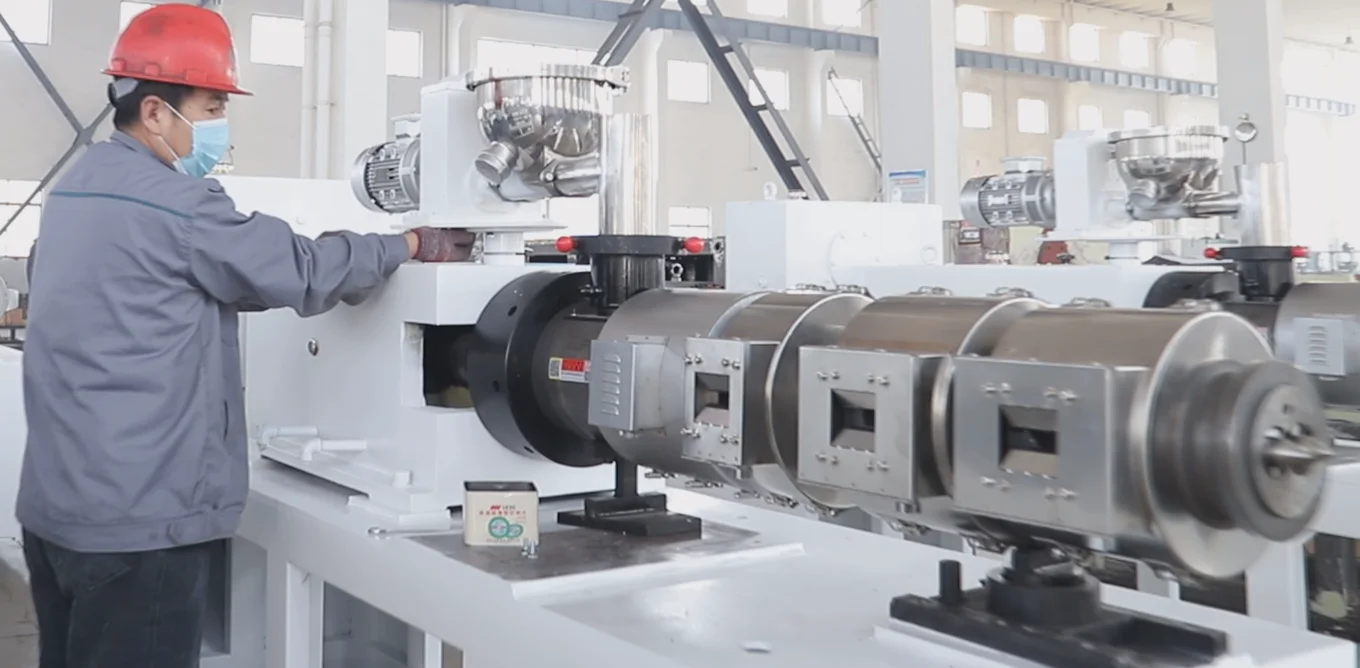

1220*2440mm Pvc Skinning Foam Board Extrusion Machine Manufacturer From Jiangsu CHINA

1220*2440mm Pvc Skinning Foam Board Extrusion Machine Manufacturer From Jiangsu CHINA